Supply Chain Logistics

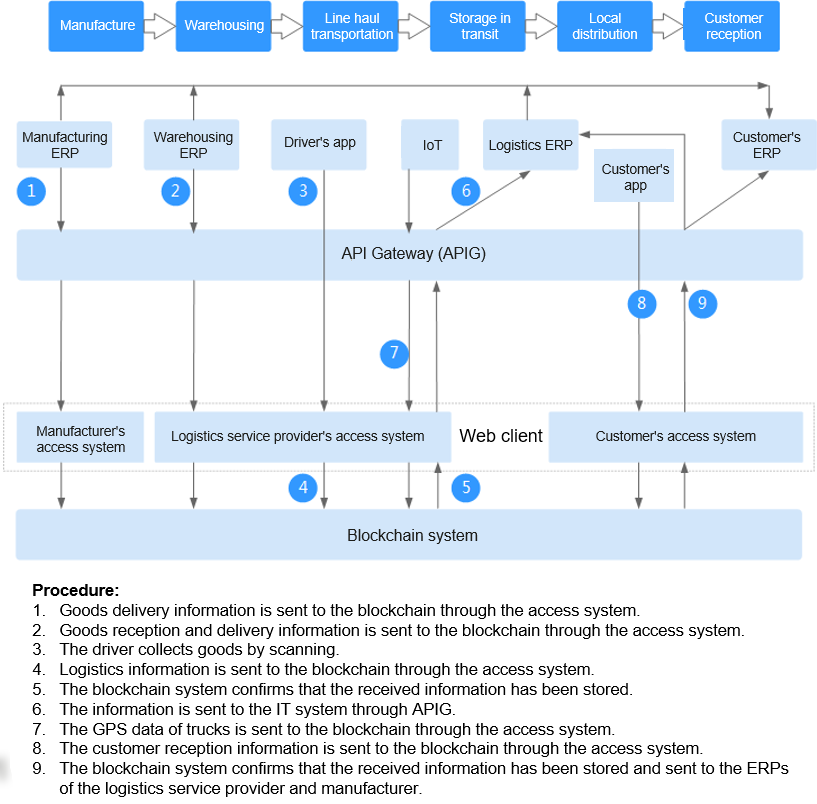

Manufacturers, warehousing institutes, logistics providers, and customers can use BCS to comprise collaboration consortia and use IoT technologies to record all the logistics information of goods, including production, warehousing, line haul transportation, reselling, and local logistics. The consortia break down information silos, improve circulation of information, and build trust between parties.

Industry Status Quo and Pain Points

- Disadvantage of using paper documents

Many phases of logistics still involve manual operations and paper documents. This causes long duration of the process, high costs, slow reconciliation, and risks of document losses or damage. The cost on maintaining and transferring documents accounts for 1/5 of the total logistics cost.

- Low efficiency

Participants in a supply chain have their own information systems, independent from each other. There is no unified standard or system. It is difficult for them to collaborate effectively.

- Long duration

Electronic information can be easily tampered with. Therefore, paper documents are used as the only type of proof for settlement, but extend the accounting period and the carriers' average collection period of receivables.

- Difficult financing

Most carriers are small- and medium-sized enterprises, lacking credit records, scores, or credibility. Financing is difficult and requires high costs.

Solution Architecture

The supply chain logistics solution provided by BCS can be combined with the IT information systems of logistic participants to achieve the following:

- Jointly maintain unified ledgers, which store immutable and traceable goods transfer records to meet audit requirements.

- Provide common APIs for participants' IT systems to access BCS and input data, which cannot be tampered with. In this way, participants establish their credibility and trust in each other.

- Automatically store the geo-fence information reported by the driver's app to show in real time when, where, and by whom goods are processed.

- Fulfill smart contracts to automatically perform signing, settlement, and calculation to obtain the performance data, which is considered fair due to the automation.

Solution Highlights

- Reduced errors

Distributed, shared ledgers greatly improve the traceability and transparency of the supply chain and effectively reduce or eliminate changes of frauds and errors.

- Increased efficiency

Electronic proofs of delivery (PODs) are used instead of paper documents to reduce the delay caused by paper works. Smart contracts enable automatic settlement to improve efficiency.

- Lower costs

Quick settlement, automatic order reception, and goods follow-up significantly lower the logistics costs of all the involved parties.

- Transparent audit

Immutability of distributed ledgers and non-repudiation of signatures allow for quick discovery of problems in supply chain logistics.

- Trust

In addition to transparent rules and automated settlement, the blockchain technology can help you follow goods all the way through production and transport to final reception. These mechanisms greatly improve the trust between all the involved parties.

Feedback

Was this page helpful?

Provide feedbackThank you very much for your feedback. We will continue working to improve the documentation.See the reply and handling status in My Cloud VOC.

For any further questions, feel free to contact us through the chatbot.

Chatbot